- [email protected]

- +86 166 2512 2612

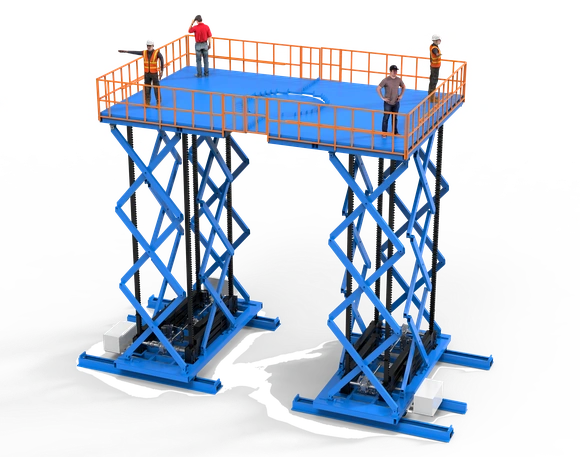

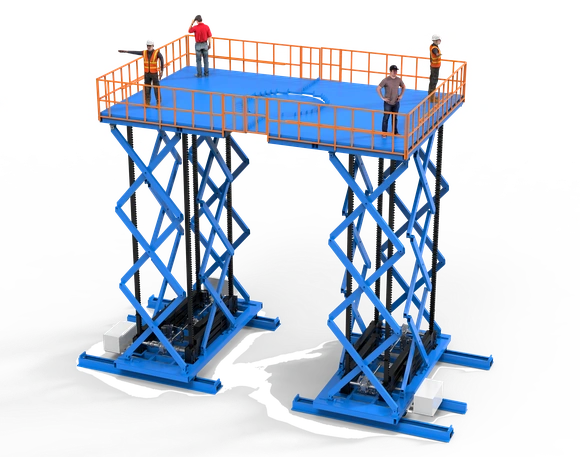

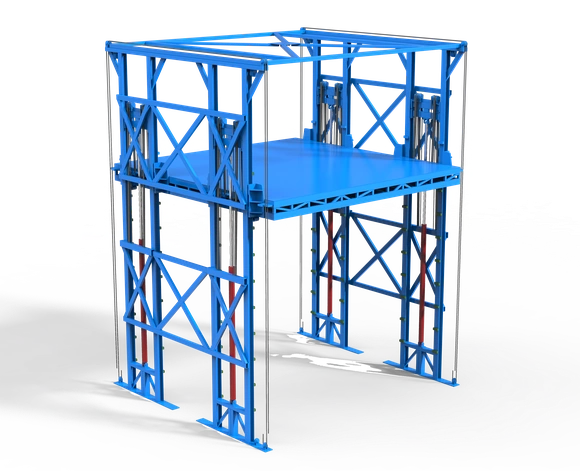

High-capacity vertical lifts and hydraulic platforms built for continuous operation in demanding environments.

Find the right solution for your needs. Browse our extensive catalog by product type or by your specific industry application.

Seamless integration with AS/RS systems for high-speed automated vertical logistics and pallet handling.

Specialized lifting solutions for automotive assembly lines, 4S showrooms, and multi-level parking systems.

Ergonomic lifting tables designed to optimize manufacturing workflows and assembly line efficiency.

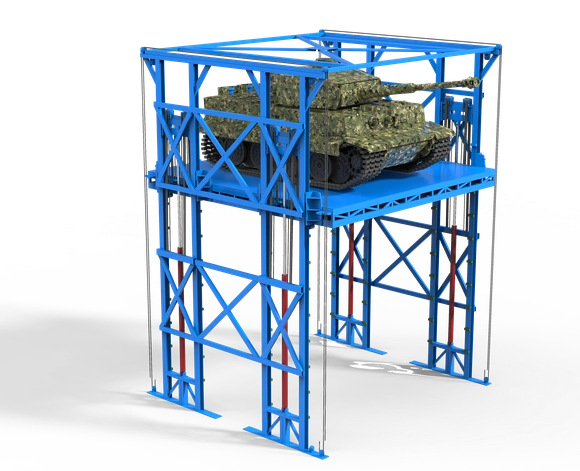

Robust handling solutions for extreme loads, steel coils, and heavy machinery testing with maximum safety.

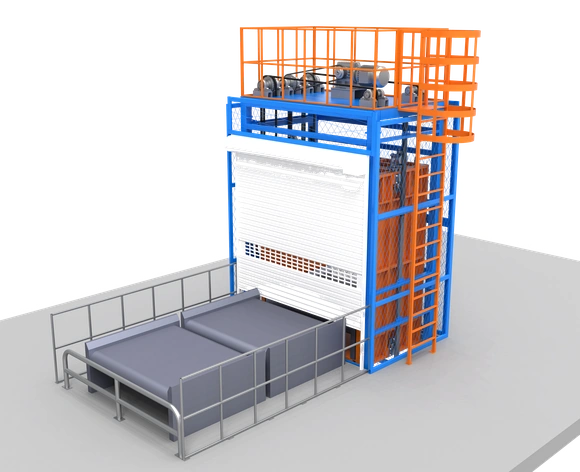

Efficient inter-floor goods transport for mezzanines, loading docks, and commercial buildings.

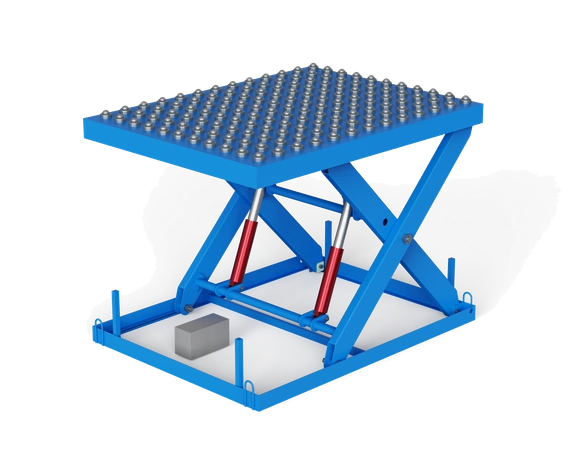

Heavy-duty hydraulic lift tables for production lines and docks. Fully customizable platform size and capacity.

Heavy-duty hydraulic lift tables for production lines and docks. Fully customizable platform size and capacity.

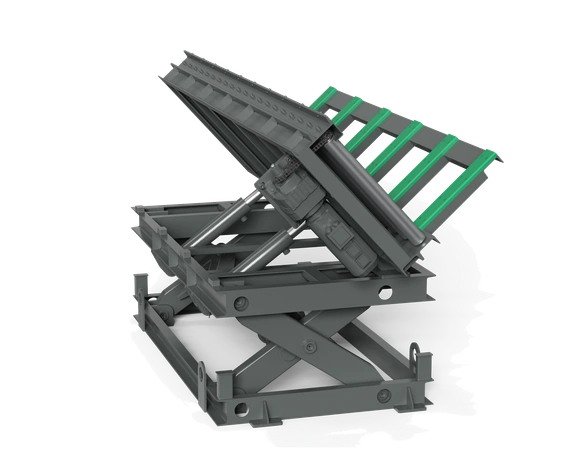

Engineered for rotating heavy coils and molds by 90° or 180° with smooth, precise hydraulic control.

Cost-effective vertical freight elevators for factories. A reliable, heavy-duty alternative to traditional elevators.

At GRADIN, we understand that standard specifications do not fit every warehouse. With over 15 years of manufacturing expertise, we bridge the gap between heavy-duty performance and precise engineering. Whether you need a specialized mezzanine lift for a tight space or a fleet of aerial work platforms, our dedicated R&D team turns your challenges into efficient, certified realities.

Honest insights from international users across diverse industries, reflecting real performance in real environments.

Ordered a 10-ton overhead crane for our new facility. The customization process was seamless, and the engineering team responded to every modification request within 24 hours. Quality exceeds our expectations—been running flawlessly for 8 months.

We collaborate with leading companies worldwide to deliver reliable and innovative lifting solutions.

Yes. All major products support customization, including lifting height, load capacity, platform size, track length, motor configuration, and voltage. We design complete solutions based on your workshop layout and working conditions.

Three key details are enough: load capacity (tons), lifting height, and available installation space. If you have a layout drawing, our engineers can provide a quick technical proposal and quotation.

We can produce according to CE, ISO, EN, FEM standards. Voltage and certifications can be adapted for Europe, North America, Southeast Asia, and the Middle East.

Standard models take 10–15 days. Heavy-duty or non-standard customized projects usually require 20–35 days depending on design complexity.

For most overseas projects, we offer remote installation support (video + documentation + online assistance). On-site service can be arranged depending on the project and country.

Main structural components have a 1-year warranty. Electrical parts follow brand warranties. We provide troubleshooting via video, replacement parts, and technical support when needed.

Yes. We can customize your brand logo, nameplate, color, and packaging. Full ODM development is also available based on your design requirements.

Most shipments go by sea (FCL/LCL). Large structures are packed in reinforced frames or heavy-duty crates. Export-standard packaging ensures the equipment won’t deform during transport.

The quote includes the equipment, standard accessories, control system, basic drawings, installation manual, and after-sales support. Extra items like rails, steel structures, or specific electrical brands will be listed separately.

Professional manufacturer of aerial work platforms and hydraulic lifts. Specializing in OEM customization and factory-direct solutions.

Sector # 48, 123 Street, miosya road VIC 28, Australia.

+8615800125621

Subscribe to our Newsletter to be updated. We promise not to spam.

Copyright © 2025 GRADINMachinery. All Rights Reserved