Vertical Reciprocating Conveyor

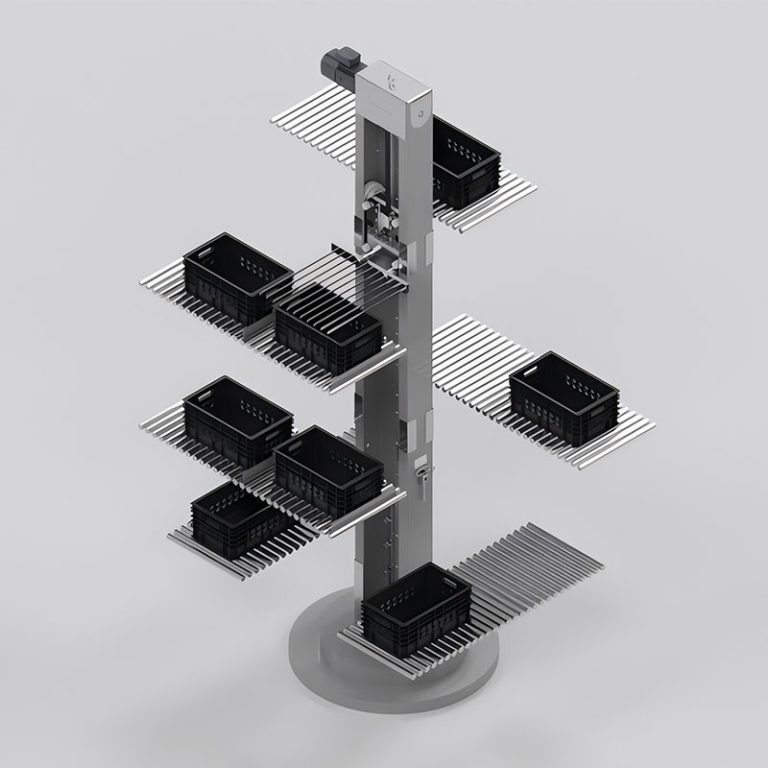

Optimize vertical transportation, enhance operational efficiency, and ensure safe load handling with our advanced Vertical Reciprocating Conveyors (VRCs) designed for seamless movement of palletized goods across multiple levels.

To find out more talk to our team

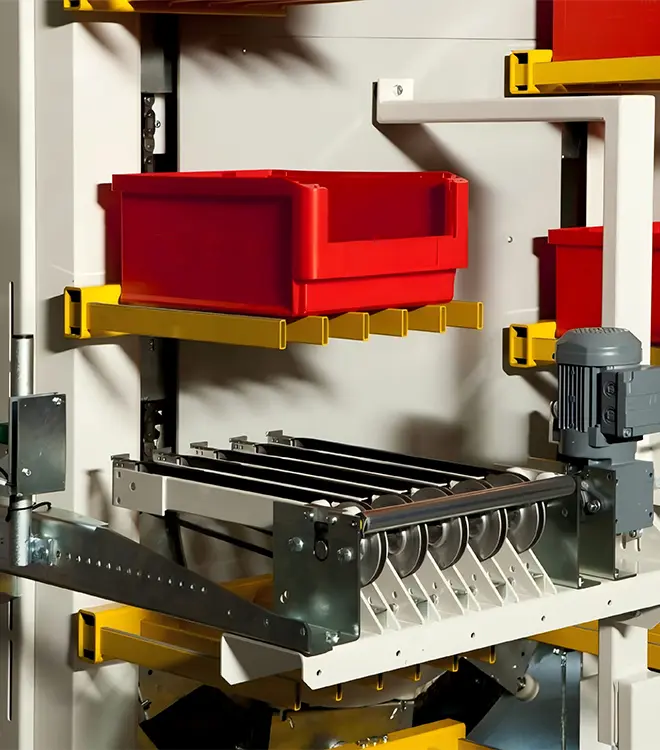

Minimalist guardrail design cuts costs: Uses fewer enclosures to ensure safety and improve cost-effectiveness.

Loading and unloading options: Supports C-type unloading (same side) and Z-type unloading (opposite side) to fit different logistics processes.

Versatile for various cargo sizes: Designed to easily handle different weights and dimensions of materials.

Efficient vertical transport: Quickly and safely moves goods between levels, enhancing operational efficiency.

Want to know more? Our helpful

team are here to help.

Request a quote

View our range of vertical reciprocating conveyor

Vertical reciprocating conveyor frequently asked questions

Installing a Vertical Reciprocating Conveyor (VRC) may require structural modifications, depending on its design, capacity, and installation environment. Below is a professional analysis:

Structural Requirements for VRC Installation

Floor Reinforcement

- Light-duty VRCs (<1,000 lbs/450 kg): May only need localized floor strengthening (e.g., steel plates or cross-bracing).

- Heavy-duty VRCs (>2,000 lbs/900 kg): Require concrete footings or steel I-beam supports to safely distribute loads (in accordance with ANSI/ASME B20.1).

Vertical Shaft Considerations

- Guided Systems: Need structural alignment with building columns or dedicated steel frameworks for guide rails.

- Clear Height: Minimum overhead clearance (typically 12–18 inches above the travel path) must be maintained.

| VRC Type | Standard Capacity Range | Maximum Capacity* |

|---|---|---|

| Standard Industrial VRC | 1,000 – 20,000 lbs (450 – 9,000 kg) |

50,000 lbs (22,680 kg) |

| Hydraulic VRC | 5,000 – 30,000 lbs (2,270 – 13,600 kg) |

100,000 lbs (45,360 kg) |

The above represents the average market prices for VRCs and does not reflect Gradin’s pricing. For specific pricing, please consult our professional team.

| VRC Type | Capacity Range | Base Price Range* | Key Cost Drivers |

|---|---|---|---|

| Standard Electric VRC | 1,000-5,000 lbs (450-2,270 kg) |

$15,000 – $35,000 | Platform size, lift height, control system |

| Hydraulic Industrial VRC | 5,000-20,000 lbs (2,270-9,070 kg) |

$40,000 – $85,000 | Hose/pump capacity, structural reinforcements |

| Custom Heavy-Duty VRC | 20,000-100,000+ lbs (9,070-45,360+ kg) |

$90,000 – $250,000+ | Specialized guides, explosion-proofing, automation |

Critical Cost Components:

- ✓ Drive System: Electric (15% cheaper) vs Hydraulic (higher duty cycles)

- ✓ Lift Height: Adds $800-$1,500 per additional floor (≥10 ft/3m)

- ✓ Controls: Basic pendant ($1.5k) vs PLC automation ($8k-$15k)

- ✓ Safety Features: ANSI-compliant gates (+$3k), light curtains (+$4.5k)