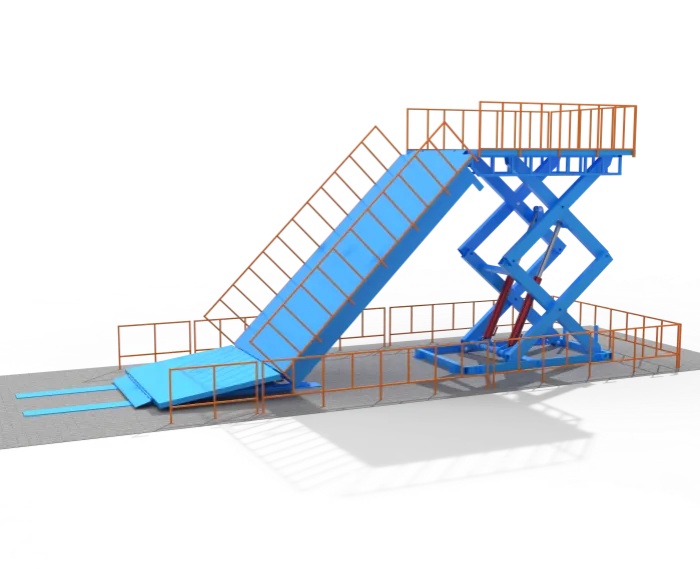

Scissor Lift Platform

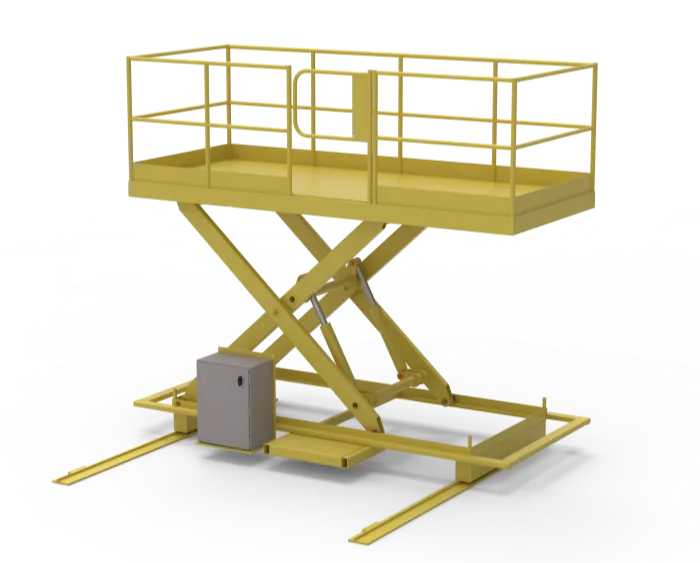

Ideal for warehouses, manufacturing, and construction, offering stable, adjustable-height access with hydraulic/electric drive options. Ensures safe, efficient material handling in confined spaces

To find out more talk to our team

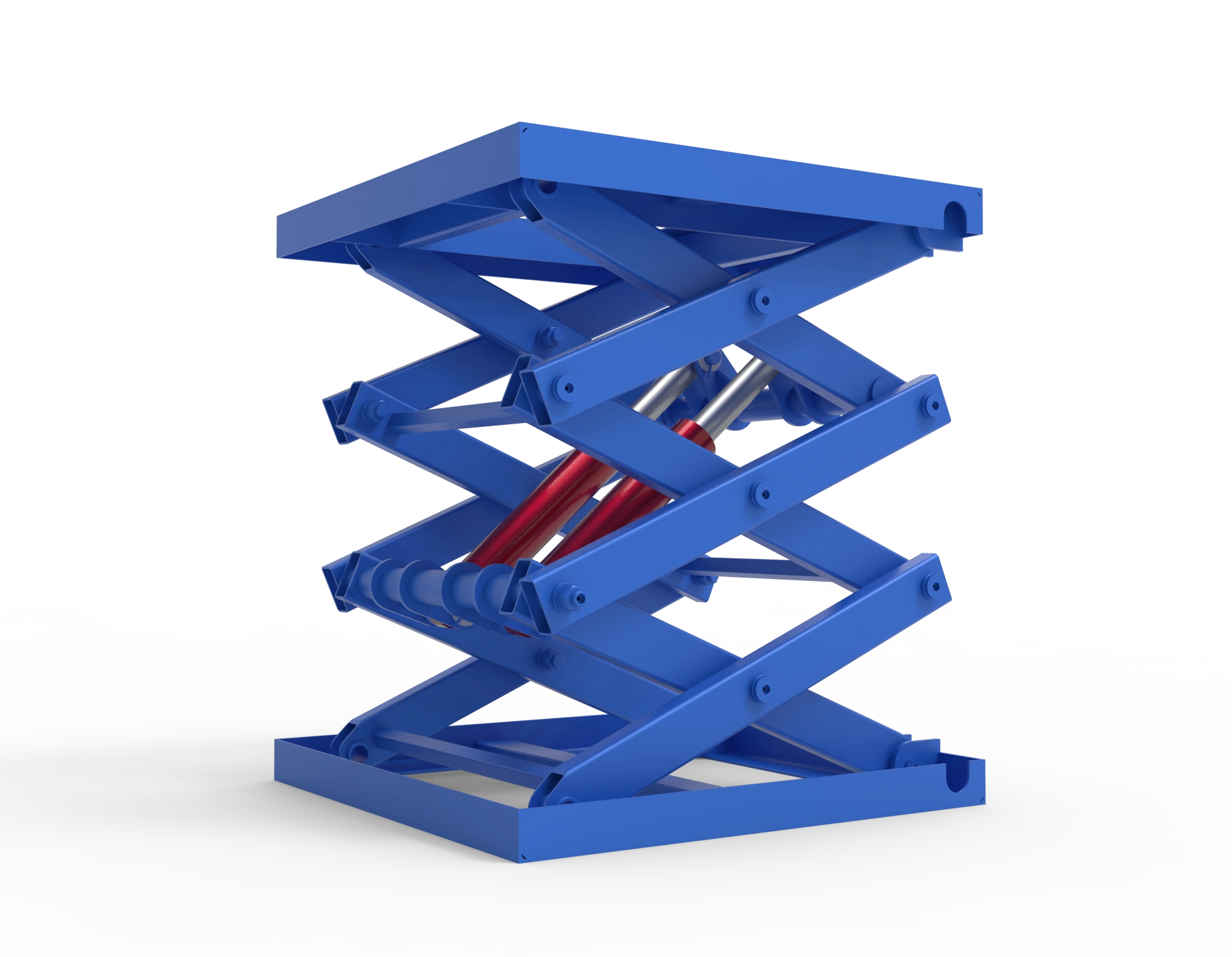

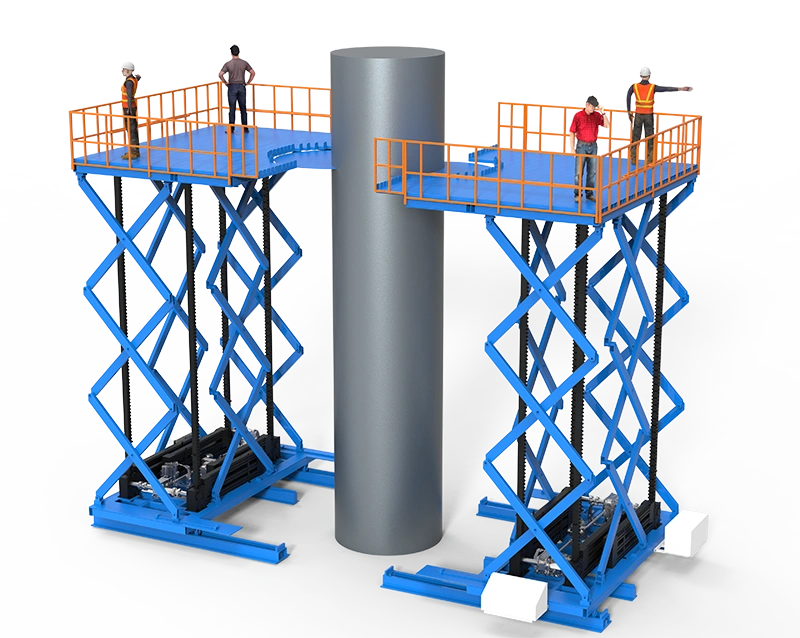

Engineered for industrial excellence, Gradin’s scissor lift platform combines heavy-duty steel construction with precision-engineered scissor mechanisms, delivering seamless vertical lifting (0.5-15m) for loads up to 100 tons.

Featuring intelligent hydraulic/electric hybrid drive systems, it ensures whisper-quiet operation and energy efficiency. Equipped with anti-slip diamond plate flooring, dual safety guardrails, and AI-powered overload sensors, it prioritizes operator safety.

Corrosion-resistant coatings and IP65-rated components enable harsh-environment durability.

Ideal for automotive assembly lines, aerospace logistics, and precision manufacturing, it redefines reliability, adaptability, and performance in high-stakes vertical material handling.

Want to know more? Our helpful

team are here to help.

Request a quote

View our range of Scissor Lift Platform

The lift is suitable for high-precision lifting operations. It can accurately locate the table height through hydraulic transmission and rigid support, realize the linear guide drive of the table, and provide accurate, stable and efficient lifting solutions for precision assembly, quality inspection and heavy-duty laboratories.

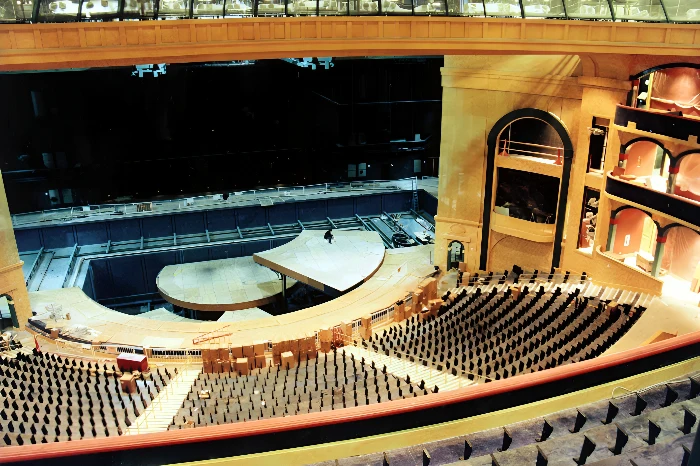

It is widely used in precision assembly, stage lifts, underwater operations, electronic manufacturing and other fields to meet high-precision lifting and lowering requirements.

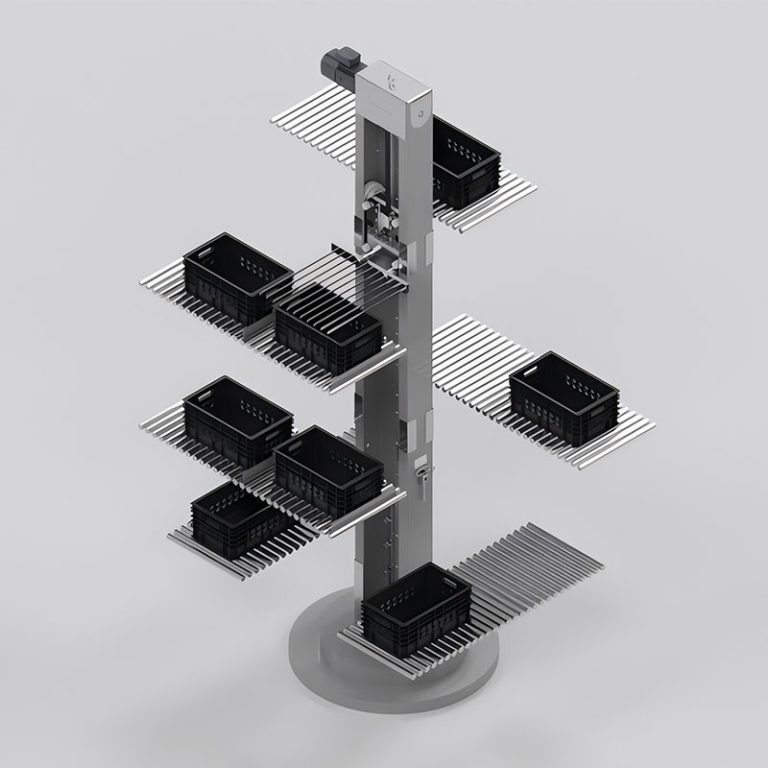

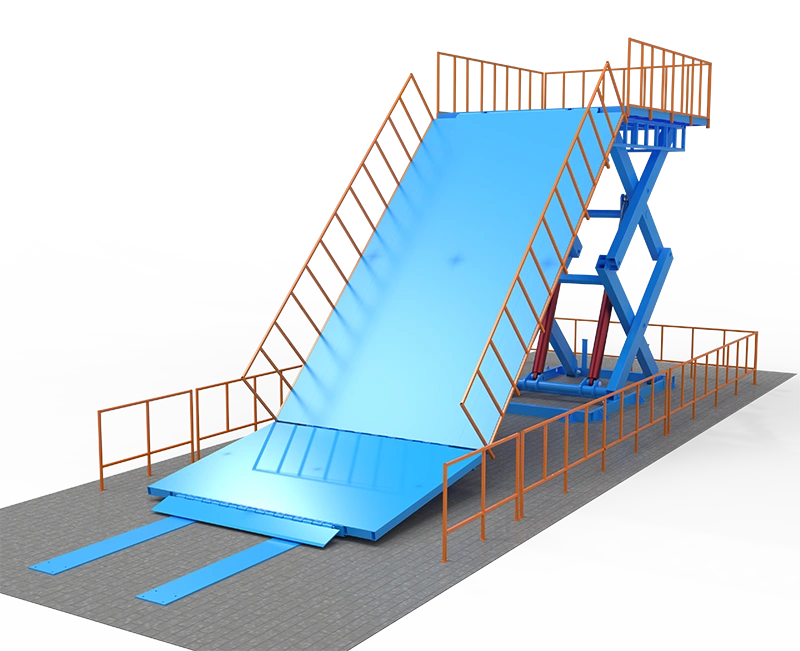

The scissor-type lifting platform can be used for various slope testing needs. The platform lifting can be wirelessly remotely controlled to control the slope angle and customize the friction of different slopes according to needs. It can be used for container cargo loading and unloading and various vehicles, machinery and equipment testing in different industries.

Widely used in container loading and unloading, testing of various machinery, vehicles and equipment.

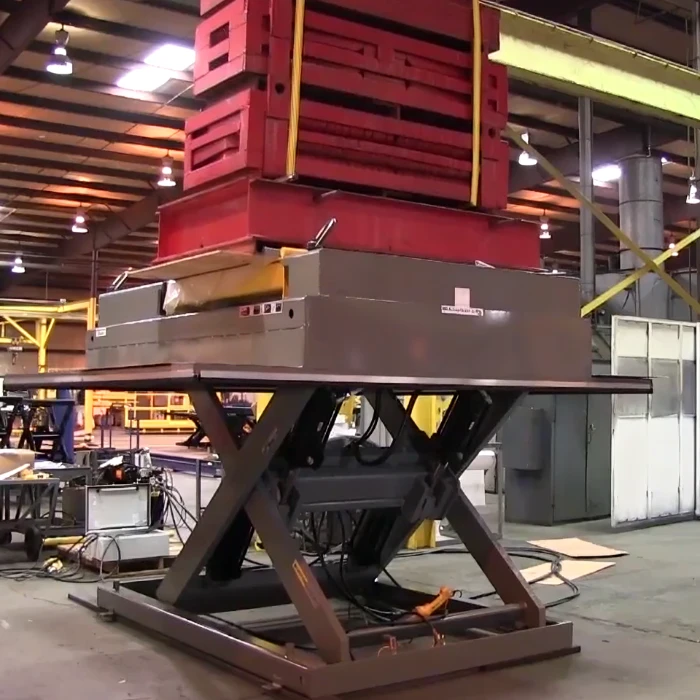

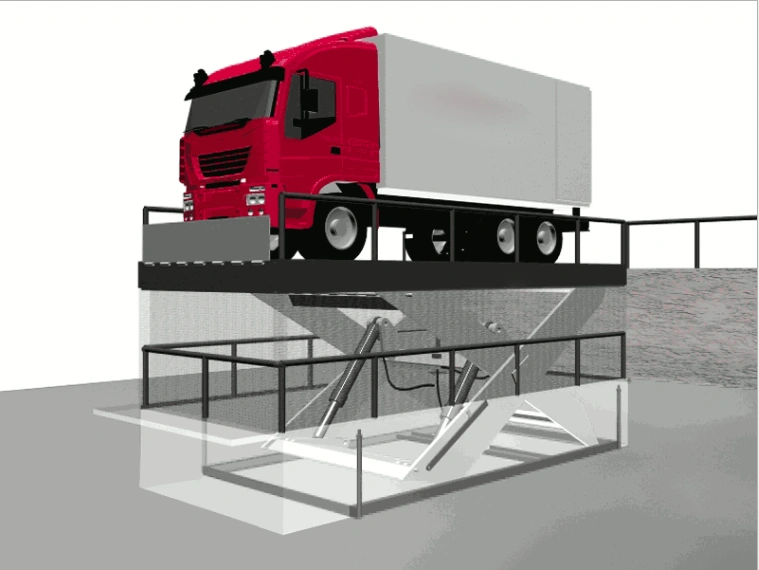

This series of products is designed for efficient and safe cargo loading and unloading, covering a variety of types such as truck lifts, scissor lifts for loading and unloading, and is widely used in logistics, warehousing, manufacturing and other industries.

These devices are designed to solve the problems of height difference, low efficiency and poor safety encountered during truck loading and unloading, ensuring the convenience of cargo loading and unloading and the safety of operators.

This lift is suitable for various scenarios such as logistics centers, warehousing, manufacturing, retail and wholesale, and can meet the loading and unloading needs of different industries.

This product provides flexible customization services and can be adjusted according to the specific needs of customers. Whether it is table customization, table height, lifting speed, load capacity or power, it can be customized according to the actual usage scenario. If customization is required, please provide the usage scenario and working conditions to maximize the special requirements of different working environments.

Safety components such as hydraulic overload protection, emergency stop buttons, and perimeter guardrails prioritize operator and equipment safety. Constructed with heavy-duty steel and weather-resistant coatings, it withstands harsh environments, while modular designs allow customization for specific facility needs.

Ideal for high-volume logistics, manufacturing, and cold storage applications, this dock lift minimizes downtime, improves ergonomics, and ensures seamless transitions between dock and vehicle, making it indispensable for modern supply chain operations.

The maximum height of the scissor lift platform is 6 meters(customizable), and the ramp’s incline angle supports flexible adjustment from 0° to 45°.

This device is suitable for industrial testing, agricultural machinery inspection, and other scenarios, particularly for high-precision and high-safety performance assessments of heavy equipment such as lawn mowers.

View our Cases of Scissor Lift Platform

Scissor Lift Platform frequently asked questions

A: Optional configurations include:

- IP54-rated motors (dust/waterproof)

- High-temperature hydraulic fluid (-20°C to 80°C)

- Stainless steel frame/anti-corrosion coating

A: Three-tier protection system:

- Mechanical: Hydraulic locks, dual support arms

- Electronic: Tilt alarm (>3° auto-lock)

- Emergency: E-stop buttons, manual pressure relief valves

A: Tiered maintenance plan:

- Daily: Hydraulic fluid checks

- Monthly: Joint lubrication

- Annual: Seal inspections