Modular Circulating Vertical Conveyor

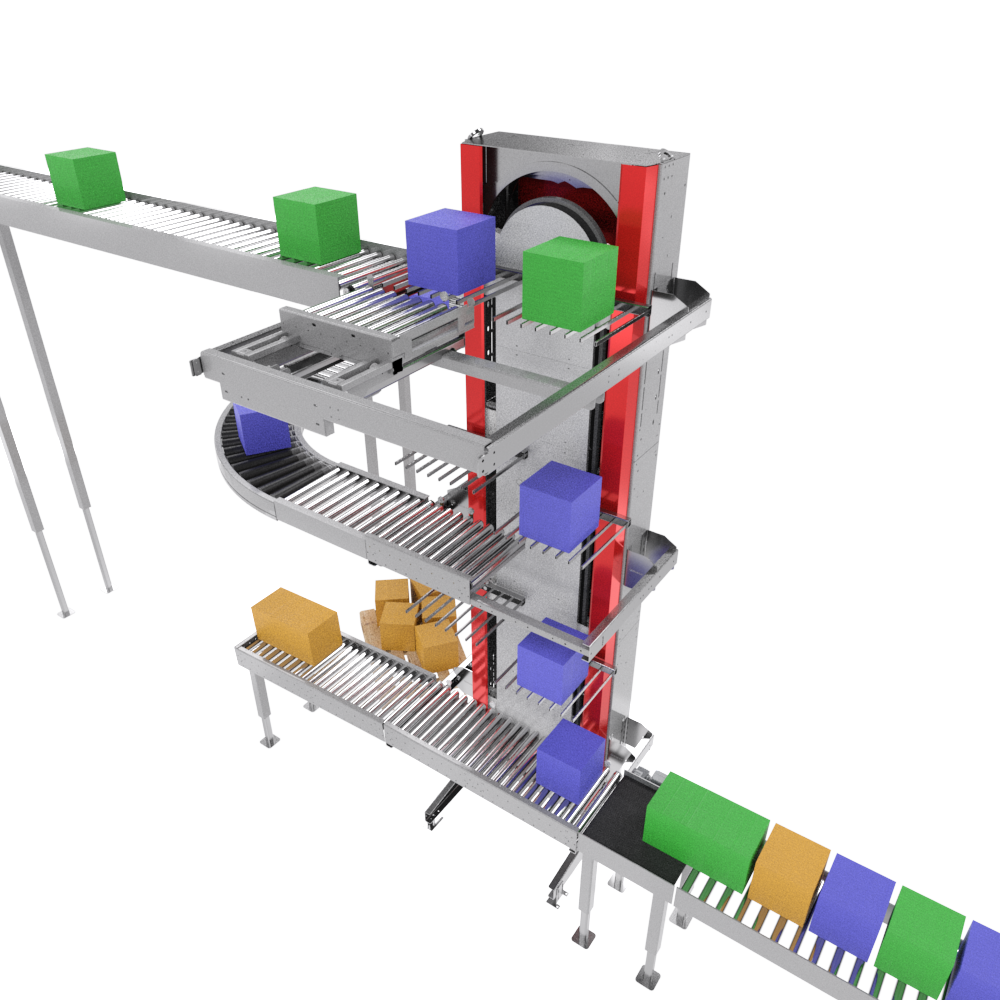

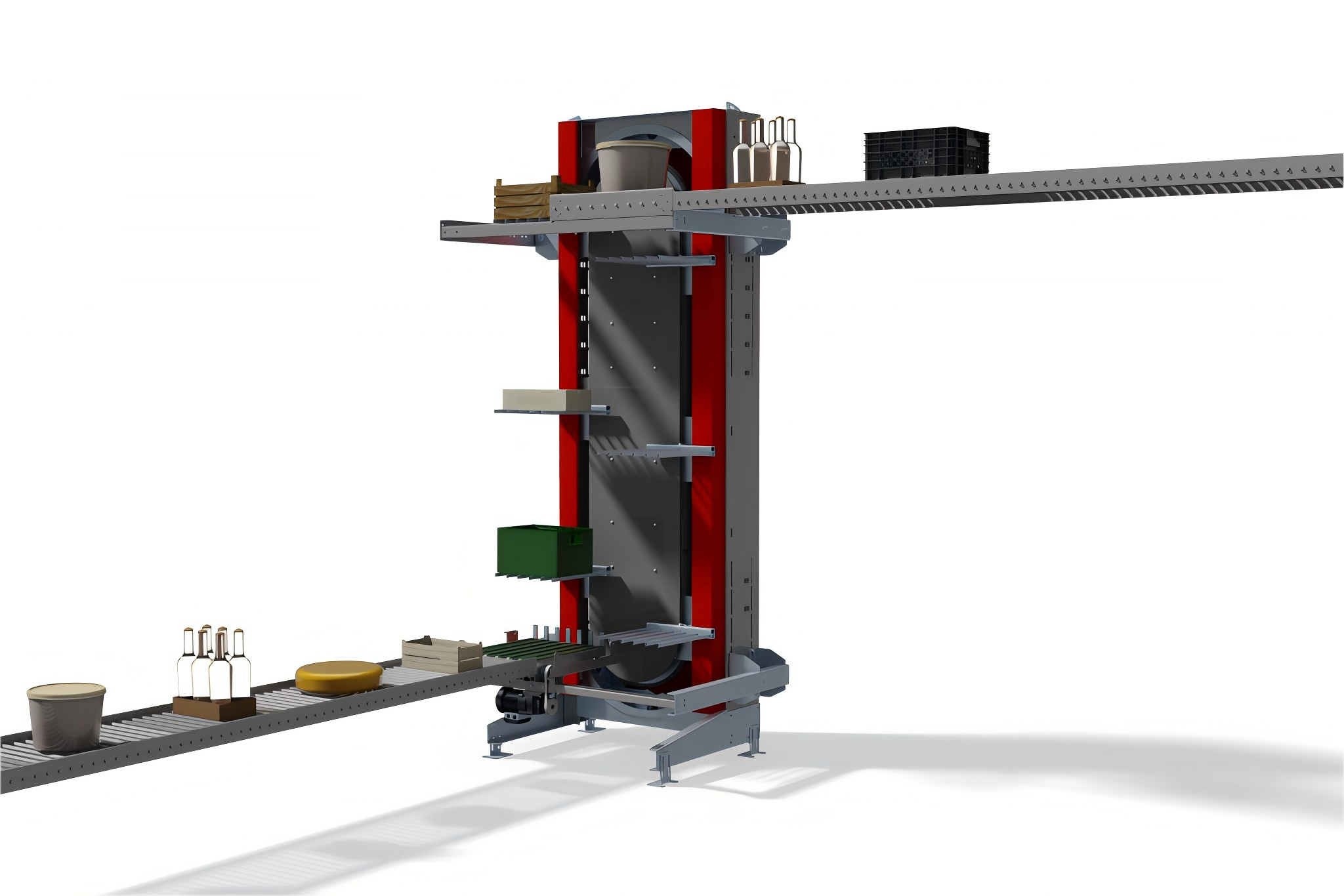

This modular circulating vertical conveyor is a continuously operating vertical transport system designed specifically for medium to high throughput material handling applications, offering exceptional cost-effectiveness. With a modular design, it is compact, easy to install, and reduces both shipping and installation costs. Even during continuous operation, it delivers excellent performance with a maximum throughput capacity of up to 2,000 products per hour, making it an ideal solution for efficient logistics and automated production lines.

To find out more talk to our team

Specification

Load: Suit your requirements

Platform size: Suit your requirements

4-8 weeks from order to install

Contact a dedicated salesperson for a quote

Enquire hereFeatures

🔹Continuous Vertical Transport: Maintains products in an upright position during movement, ideal for high-frequency and multi-floor operations.

🔹High Throughput Capacity: Handles up to 2,000 items per hour, meeting the demands of fast-paced logistics environments.

🔹Modular Construction: Enables flexible configuration, easy transportation, installation, and maintenance.

🔹Bidirectional Flow Support: Capable of simultaneous upward and downward transport to maximize space efficiency.

Enquire here

Options & Accessories

🔹The conveyor is suitable for handling a wide variety of product types such as boxes, trays, cases, and bagged goods. It can efficiently move items between multiple floors while keeping them upright throughout the entire process to avoid product tilting, damage, or deformation. This continuous lift also supports dual-direction transport—both upward and downward—and can be configured as a vertical sorter with the addition of retractable conveyors.

🔹The platform size, load capacity, and lifting height can be tailored according to the specific use case to ensure optimal compatibility. Additionally, the equipment allows for entry and exit in different directions and offers various forms of conveyor systems, providing flexibility to adapt to different material transportation modes, thereby enhancing operational efficiency.

Enquire hereThe Material Handling Equipments in your industry

The Reach 25 goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Reach 25 goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.