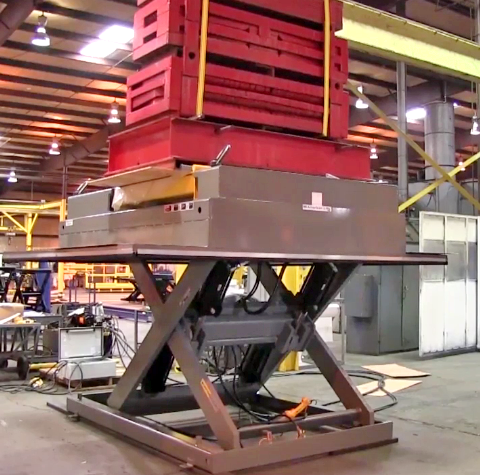

Coil Handling 20-Ton Lift

The heavy-duty material handling lift platform is specifically designed for the vertical transportation and loading/unloading of heavy materials, featuring high load-bearing capacity and exceptional stability. The platform employs multiple scissor-lift structures and an efficient hydraulic system for safe and smooth lifting and lowering of heavy-duty cargo, meeting the needs of industries such as manufacturing, warehousing logistics, and heavy equipment assembly.

To find out more talk to our team

Specification

Load: 20T,Suit your requirements

Platform size: Suit your requirements

4-8 weeks from order to install

Contact a dedicated salesperson for a quote

Enquire hereFeatures

🔹Customized heavy-duty scissor lift capable of handling 20 tons, with a shuttle platform that can transport 3-4 shuttles for coil loading and unloading applications.

🔹Equipped with high-strength precision cylinders and imported seals for excellent sealing performance, preventing leaks and enhancing overall equipment safety.

🔹The platform features high-quality baked paint for rust resistance and corrosion protection, with reinforced steel plates for enhanced load-bearing capacity.

🔹The compact and stable structure is designed to withstand high-frequency continuous operation.

Enquire here

Options & Accessories

🔹This type of lift platform can be customized according to specific production requirements. Whether it’s the platform size, load capacity, lifting height, control method, or safety features, it can be optimized based on the customer’s specific needs to ensure the equipment perfectly matches the on-site environment.

Enquire hereThe Material Handling Equipments in your industry

The Reach 25 goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Reach 25 goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.