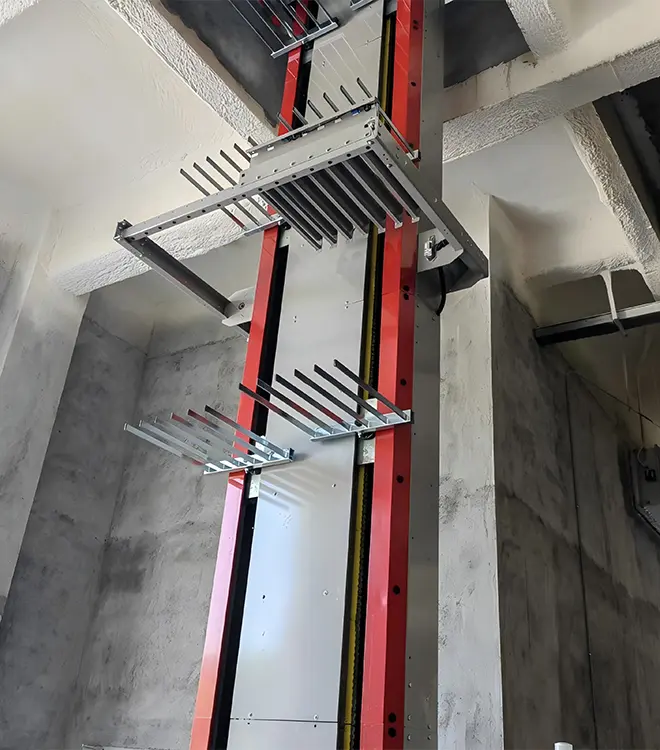

Circulating Vertical Conveyors

It is combined with the import and export conveyor lines to form a complete continuous lifting system, realizing multi-floor, multi-in and multi-out automated operations, saving space and improving efficiency.

To find out more talk to our team

Specification

Capacity: ≤ 2000kg

Platform size: Suit your requirements

Maximum working height: 15m

Cycle beat: 20 to 60 sec/time (depending on height and speed)

4-8 weeks from order to install

Contact a dedicated salesperson for a quote

Enquire hereFeatures

🔹 Simple structure and modular design: The design is simple and easy to understand, with a small number of moving parts and a closed drive device, compact structure, and easy assembly, ensuring efficient and safe operation of the equipment.

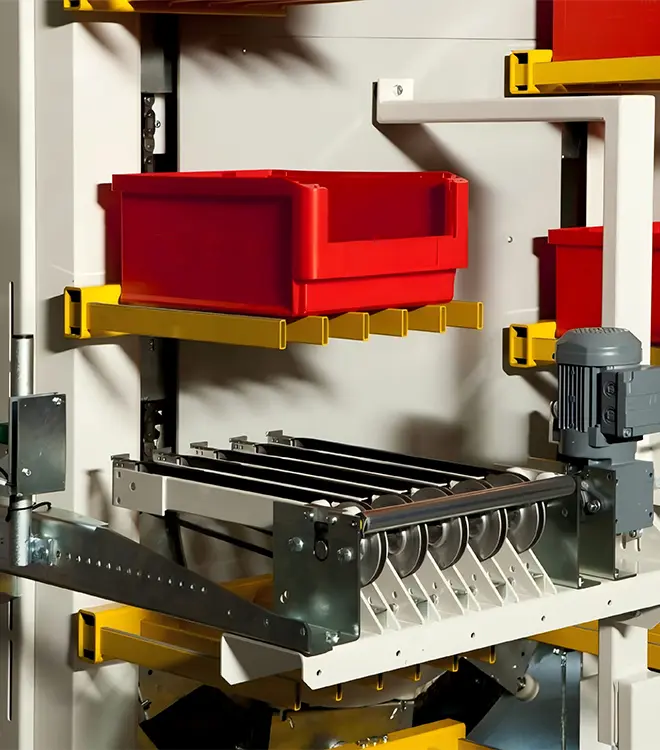

🔹 Multifunctional transportation: It supports vertical material transportation and can realize horizontal transportation, adapting to the transportation needs of various items and meeting various working environments.

🔹 Efficient operation and sorting: The equipment runs smoothly and is easy to maintain. It is suitable for cross-floor material transportation, supports efficient automatic sorting, optimizes logistics processes, improves work efficiency and saves space.

🔹 Automated handling: Used in conjunction with a flat conveyor to achieve automatic handling, reduce manpower operations, and improve work efficiency.

Enquire here

Options & Accessories

🔹The platform size and height can be customized according to your cargo conditions.

🔹The equipment supports a variety of matching connection conveying methods, including roller conveying, chain conveying, plate chain conveying, etc., which can be selected according to your specific situation.

Enquire hereGradin’s reciprocating elevator really exceeded our expectations! The equipment runs very smoothly, with low noise and high efficiency, which is a perfect match for the material handling needs of our production line. The load capacity is solid, the safety protection measures are also in place, the operation is simple and easy to understand, and the employees can get started quickly.

The Material Handling Equipments in your industry

The Reach 25 goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Reach 25 goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.