28.4.2025 / 3 minute read

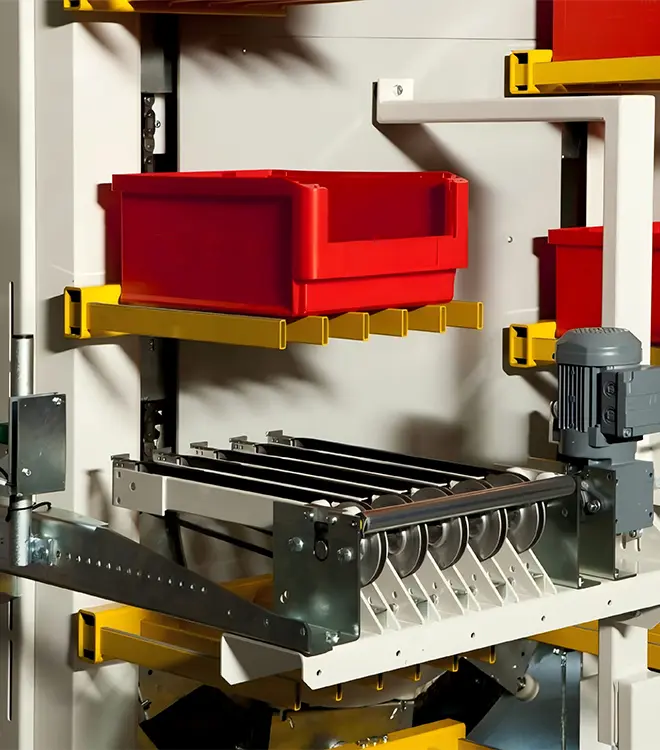

VRC Straddle Lift: Efficient Vertical Transport Solution for Modern Warehouse Logistics

Key points –

- Improve space utilization and achieve high-density storage.

- High-efficiency transportation and optimized logistics turnover.

- High carrying capacity to meet diverse logistics needs.

- Energy saving and environmental protection, reducing operating costs.

Application Scenario Analysis

E-commerce warehousing and sorting center: Orders fluctuate greatly, and rapid sorting is required during peak hours. Use VRC Straddle Lift + automatic sorting lines to achieve “goods to person” picking, and increase efficiency by 3~5 times.

Automated stereoscopic warehouse (AS/RS): Traditional stackers have high investment and insufficient flexibility. Use VRC Straddle Lift + shuttle systems to build low-cost, highly flexible dense storage solutions.

Cold chain logistics: Equipment is prone to frost in low-temperature environments, making maintenance difficult. Use antifreeze VRC Straddle Lift (stable operation at -30℃~+50℃), equipped with stainless steel guide rails + food-grade lubrication.

In-plant logistics in the manufacturing industry: The handling efficiency of heavy materials is low and there are great safety hazards. Use large-tonnage VRC Straddle Lift (3000~5000kg) with automatic loading and unloading platforms to achieve unmanned handling.

The Challenge

In the modern warehousing and logistics system, VRC Straddle Lifts face multiple challenges, including space adaptability, efficiency bottlenecks, and adaptability to special environments. The floor height restrictions and fire regulations of traditional warehouses often restrict equipment layout. The single-channel design leads to an empty load rate of up to 40%, which seriously affects operating efficiency. Special working conditions such as low temperature icing in the cold chain environment and component wear in the dusty environment place even more stringent requirements on equipment reliability. These factors together constitute the technical barriers that elevators need to break through in warehousing applications, and also directly affect the overall operating costs and service quality of the logistics system.

Solutions

In response to these challenges, a series of innovative solutions can be developed. Ultra-thin columns and foundation-free installation technology can significantly improve space utilization, dual-channel dynamic counterweight system and laser positioning technology can be used to increase operating efficiency to 600 boxes/hour, and explosion-proof electrical systems and cold chain-specific models can be developed to meet special environmental requirements. These technological advances can enable VRC Straddle Lifts to be perfectly integrated into modern intelligent warehousing systems.

Advantages

With its high efficiency, high density and intelligent features, VRC Straddle Lifts are reshaping the vertical transportation mode of modern warehousing and logistics. Whether it is e-commerce sorting, cold chain warehousing, or smart manufacturing logistics, it can provide reliable, energy-saving and low-maintenance solutions. In the future, with the deep integration of automation and AI technology, VRC Straddle Lifts will become the core infrastructure of smart warehousing.

Gallery