29.4.2025 / 3 minute read

New Breakthrough in Intelligent Logistics: Circulating Vertical Conveyor Enables Modern Production Workshop Upgrade

Key points –

- Continuous and efficient operation.

- Precise intelligent control.

- Super strong environmental adaptability.

- Flexible configuration.

Application Scenario Analysis

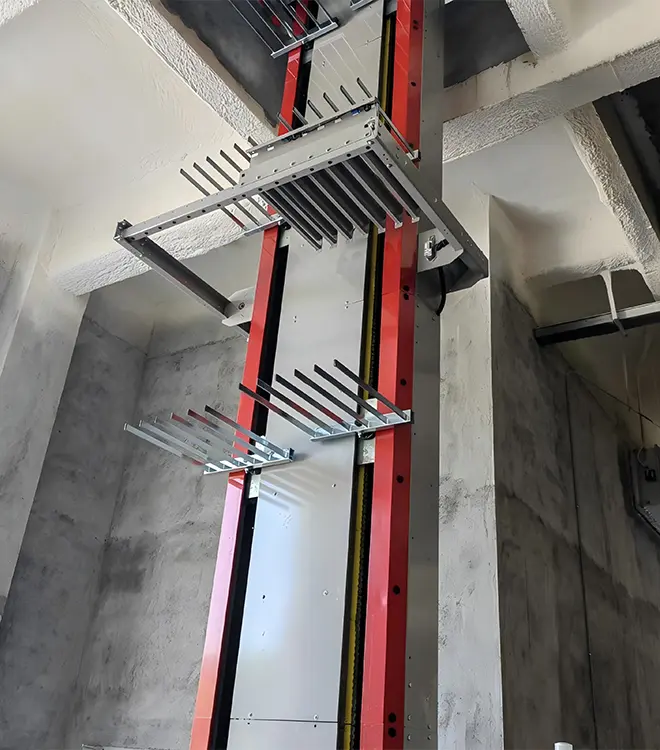

With its innovative circulation operation mode and excellent performance, the Circulating Vertical Conveyor is becoming the preferred solution for vertical material transportation in modern production workshops, bringing significant efficiency improvement and cost optimization to enterprises.

Automobile manufacturing workshop: achieving precise delivery of parts to the assembly line.

Electronic production line: Efficiently transport precision components across floors.

Food processing plants: automated conveying of hygienic raw materials.

Pharmaceutical production workshop: vertical material flow that meets GMP requirements.

The Challenge

InIn the production workshop environment, the Circulating Vertical Conveyor faces complex working conditions. The difference in the beat between different processes easily leads to material backlogs, and the diversified production materials put forward higher requirements on the versatility of the cargo platform. At the same time, environmental factors such as dust and oil pollution in the workshop will affect the long-term operation stability of the equipment, and maintenance under high-frequency use has also become an operational difficulty.

Solutions

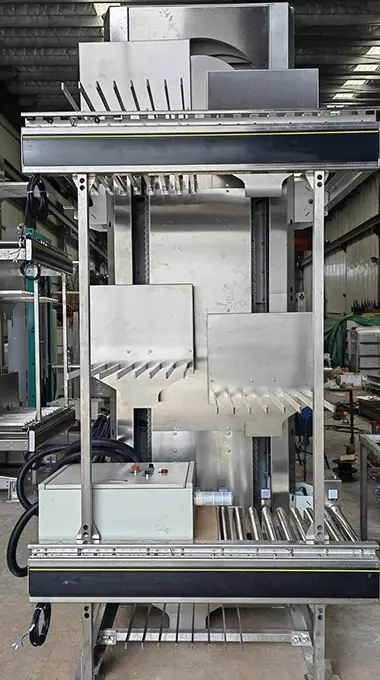

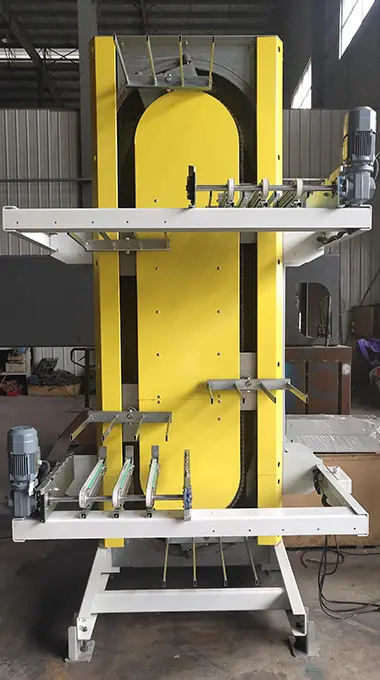

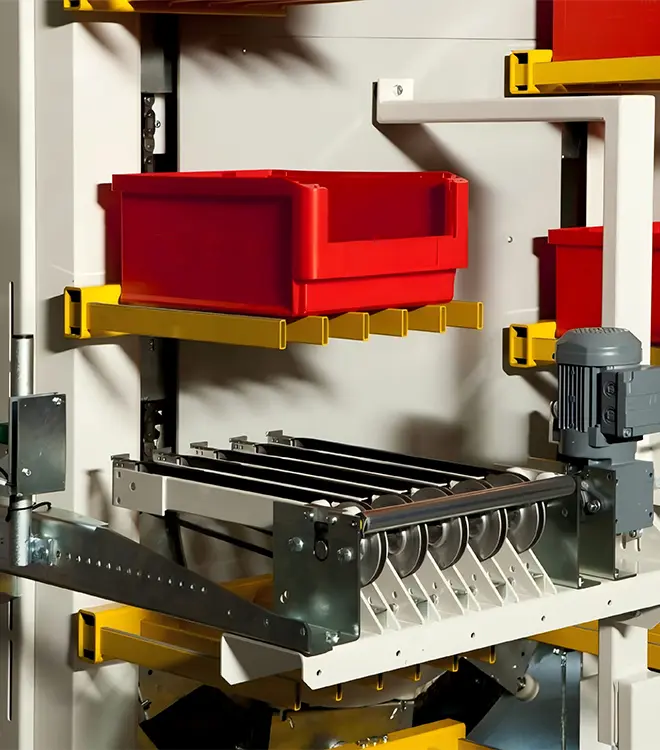

In response to the special needs of the production workshop, the new generation of equipment adopts intelligent beat adjustment technology to automatically match the operating speed of the previous and next processes. The modular fork arm design supports the rapid replacement of carriers of different specifications, easily coping with the transportation of multiple categories of materials. In addition, the key components adopt a sealed dustproof structure and a self-lubricating system, combined with the intelligent early warning function, which significantly improves the reliability of the equipment in harsh environments.

Advantages

The Circulating Vertical Conveyor brings significant efficiency innovation to the production workshop. Its continuous circulation operation mode completely eliminates the idle waiting time of traditional elevators. The compact body design can be perfectly integrated into the existing production line layout to maximize space utilization. The intelligent control system can not only accurately connect each production link, but also realize the logistics optimization of the entire workshop through data interconnection, creating an efficient and flexible intelligent production system for the enterprise.

Gallery