28.4.2025 / 3 minute read

Innovative Practice of VRC Straddle Lift in Cold Chain Logistics of Medicine and Food

Key points –

- Clean and hygienic design.

- Precise temperature-controlled transportation.

- Pollution-free operation.

- Efficient and flexible handling.

- Intelligent traceability.

Application Scenario Analysis

In the food and pharmaceutical industries, the sanitation and safety, temperature control accuracy and traceability of material handling are directly related to product quality compliance. Traditional manual handling or ordinary lifting equipment has pain points such as contamination risks and large temperature fluctuations.

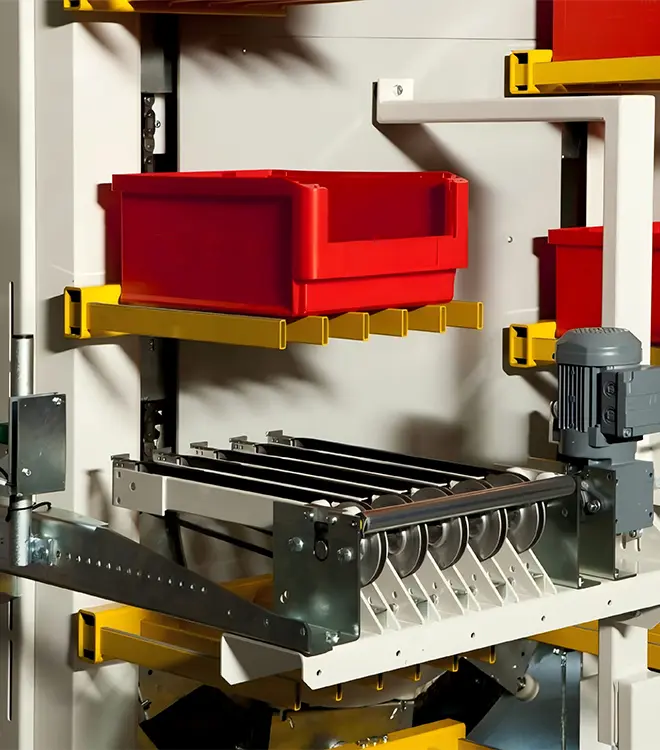

With its clean design, intelligent temperature control and traceability system, the VRC Straddle Lift is becoming a key equipment for food processing and pharmaceutical companies to optimize production logistics.

The Challenge

In the food and pharmaceutical industry, VRC Straddle Lifts face special application challenges. Strict hygiene standards require that the equipment must eliminate the risk of microbial contamination, while the particularity of pharmaceutical and food raw materials places extremely high demands on temperature and humidity control during transportation. The multi-variety, small-batch production model also requires the equipment to have the ability to quickly change models, and traditional lifting equipment often finds it difficult to meet these stringent conditions at the same time. In addition, industry regulations on mandatory material traceability have also brought new challenges to the level of intelligence in the logistics system.

Solutions

In response to these industry pain points, the new generation of VRC Straddle Lifts adopts a number of innovative designs. The all-stainless steel structure and seamless surface treatment ensure that the equipment is easy to clean and meets GMP cleanliness requirements; the modular temperature-controlled cabin can quickly adjust the transportation environment according to different material requirements; the intelligent management system automatically records transportation parameters to establish a complete material traceability chain. These improvements enable the equipment to perfectly adapt to the special needs of food and pharmaceutical production.

Advantages

The VRC Straddle Lift brings significant operational advantages to food and pharmaceutical companies. Its hygienic design effectively reduces the risk of product contamination, precise environmental control ensures the stability of material quality, and flexible configuration schemes greatly improve the adaptability of production lines. More importantly, the intelligent traceability function helps companies easily meet industry regulatory requirements. This solution that combines safety, precision, and compliance is becoming a standard choice for modern food and pharmaceutical factories.

Gallery