28.4.2025 / 3 minute read

Innovative Application of VRC Straddle Lift in Automobile Parts Assembly

Key points –

- Accurate and efficient transportation.

- High space utilization.

- Intelligent collaborative operation.

- Stable and reliable operation.

Application Scenario Analysis

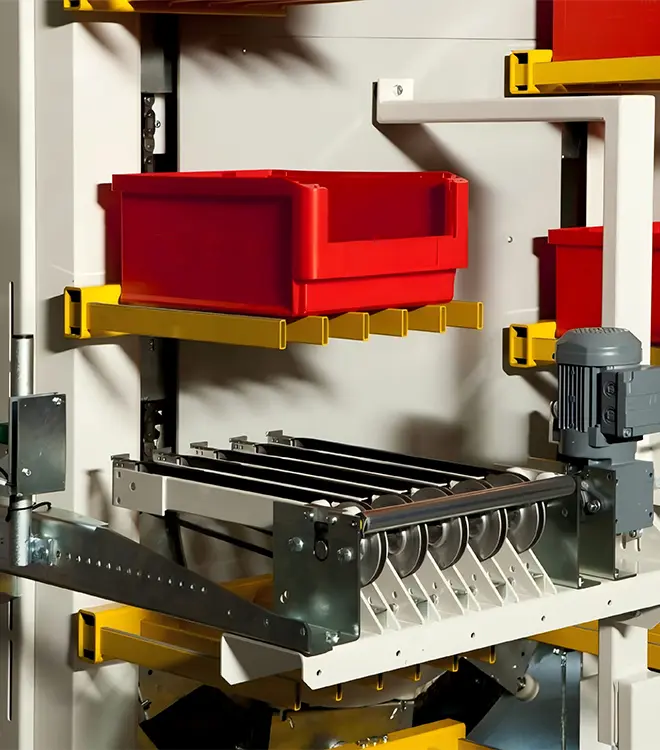

As the automobile manufacturing industry develops towards intelligence and flexibility, VRC Straddle Lifts, as key equipment for modern vertical material transportation, are demonstrating unique technical advantages in the field of automobile parts assembly.

On highly automated automobile production lines, VRC Straddle Lifts achieve intelligent transportation of large components such as engines and gearboxes through their compact structural design and precise positioning capabilities, perfectly solving the pain points of traditional cranes that occupy large spaces and have low positioning accuracy.

On highly automated automobile production lines, VRC Straddle Lifts achieve intelligent transportation of large components such as engines and gearboxes through their compact structural design and precise positioning capabilities, perfectly solving the pain points of traditional cranes that occupy large spaces and have low positioning accuracy.

The Challenge

In the process of assembling automobile parts, VRC Straddle Lifts face technical challenges brought about by special working conditions. Frequent lifting of heavy parts can easily cause slight vibrations in the equipment, affecting the quality requirements of precision assembly; the production of multiple models on the same line requires the equipment to be able to quickly adapt to parts of different specifications; factors such as oil and dust in the workshop environment also pose challenges to the long-term stable operation of the equipment. These factors jointly restrict the overall efficiency and product quality of the assembly line.

Solutions

To meet these challenges, modern VRC Straddle Lifts have adopted a number of innovative designs. The precise guide system and intelligent anti-shake technology ensure the smoothness of the component conveying process; the modular hanger design enables rapid changeover to meet flexible production needs; the fully enclosed structure and self-cleaning function effectively improve the reliability of the equipment in harsh environments. These improvements enable the hoist to be perfectly integrated into the intelligent automobile production line.

Advantages

The VRC Straddle Lift brings significant advantages to automobile assembly. Its compact structure design greatly improves the utilization of workshop space while maintaining excellent load-bearing capacity; the high-precision positioning system ensures the first-time success rate of component assembly; and the intelligent control system achieves seamless coordination with other automated equipment. These features make it a key equipment for improving automobile assembly efficiency and quality, playing an irreplaceable role in modern automobile factories.

Gallery