29.4.2025 / 3 minute read

Circulating Vertical Conveyors: The Core Power of Efficient Operation of Modern Warehousing Logistics

Key points –

- Efficient and continuous operation.

- Extreme space utilization.

- Intelligent and precise control.

- Super load capacity.

Application Scenario Analysis

E-commerce warehousing center: realize high-speed sorting and cross-floor transfer of goods.

Automated warehouse: perfect cooperation with stacker crane to complete goods storage and retrieval.

Production line material area: ensure that raw materials are delivered to each workstation on time.

Cold chain logistics center: Special design to ensure stable operation in low temperature environment.

The Challenge

In warehousing and logistics applications, Circulating Vertical Conveyors face realistic challenges such as adaptability to multiple types of goods and high-intensity continuous operation stability. Goods of different sizes and specifications have different requirements for the loading platform, and the 7×24-hour uninterrupted operation mode poses a severe test to the durability of the equipment. At the same time, seamless docking with the existing warehousing system also requires overcoming many technical difficulties, which puts higher requirements on the intelligence of the equipment.

Solutions

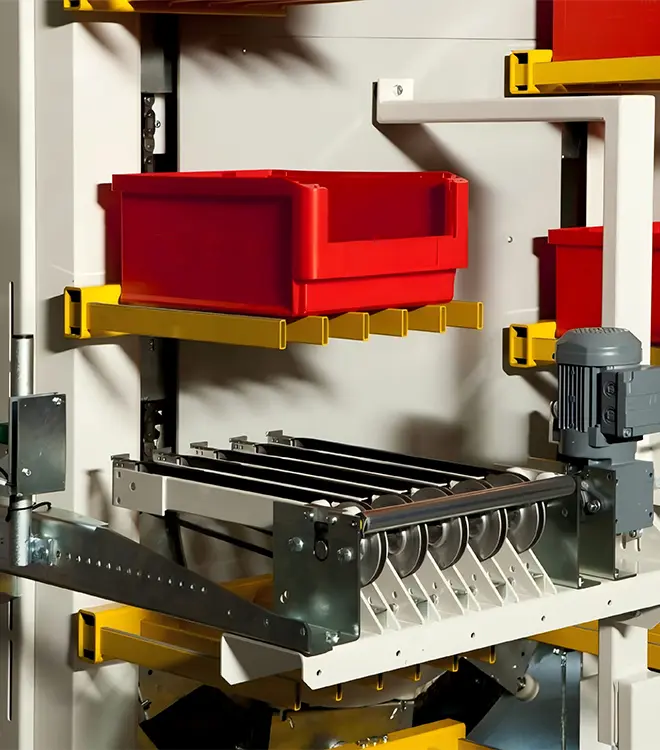

In response to these challenges, modern Circulating Vertical Conveyors use an adjustable fork-arm design, which automatically matches goods of different specifications through an intelligent recognition system. Key components use military-grade materials and long-term lubrication systems to ensure long-term and stable operation of the equipment. Through deep integration with the WMS warehouse management system, intelligent matching of equipment operating parameters and warehouse operation requirements is achieved, greatly improving system coordination efficiency.

Advantages

The biggest advantage of the Circulating Vertical Conveyor is its revolutionary improvement in operating efficiency. The continuous cycle working principle completely eliminates the idle waiting time of traditional elevators and realizes true uninterrupted operation. The compact body structure can be perfectly integrated into various storage environments, significantly improving space utilization. The application of intelligent control system not only ensures operation accuracy, but also automatically optimizes the operation rhythm according to storage needs, providing a reliable vertical transportation solution for modern logistics centers.

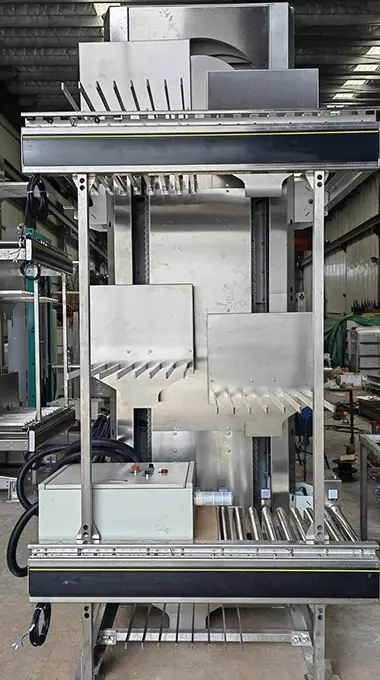

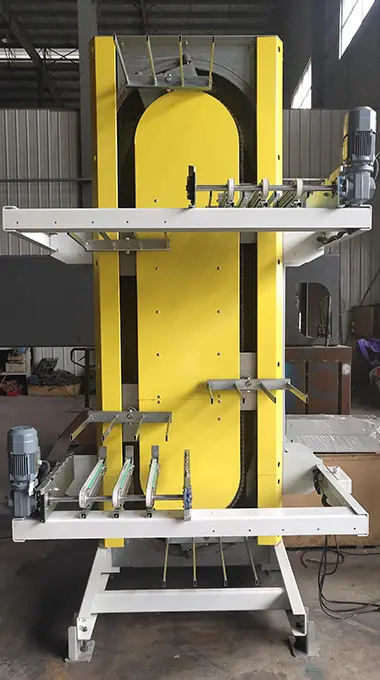

Gallery