29.4.2025 / 3 minute read

Circulating Vertical Conveyors Lead The New Wave of Intelligent Upgrades in Distribution Centers

Key points –

- Continuous cycle operation system.

- Intelligent dynamic adjustment technology.

- Super strong load adaptability.

- Data interconnection function.

Application Scenario Analysis

Express distribution center: realize high-speed cross-layer sorting of express parcels, with a peak processing capacity of over 8,000 pieces/hour.

E-commerce warehousing hub: complete the vertical transportation link of the “goods to person” picking system, and increase the picking efficiency by 3 times.

Cold chain distribution center: special materials and sealing design ensure stable operation in low temperature environment.

Cross-border logistics park: meet the rapid loading and unloading needs of containers of different specifications.

The Challenge

In the modern distribution center scenario, Circulating Vertical Conveyors face multiple operational challenges. The extreme differentiation of express specifications places strict demands on equipment compatibility, and stable handling is required for everything from light and small items to heavy and special-shaped items. The explosive workload during the peak distribution period tests the continuous operation capability of the equipment, while the 7×24-hour uninterrupted operation mode poses a severe challenge to the durability of the equipment. In addition, seamless integration with the existing sorting system also requires overcoming many technical difficulties.

Solutions

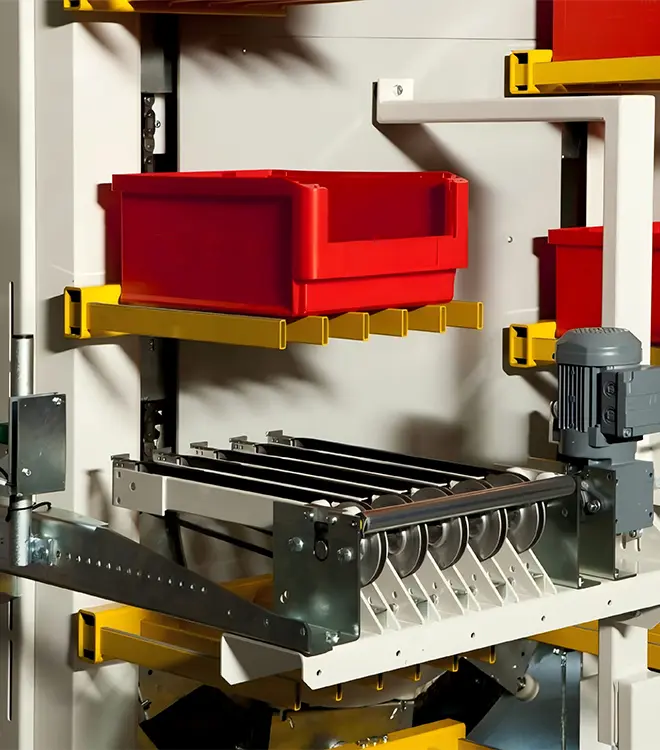

In response to these challenges, the new generation of equipment uses an intelligent adaptive fork arm system to automatically match goods of different specifications through dynamic adjustment technology. Key components use aviation-grade alloy materials and long-term lubrication systems to ensure the stability of the equipment under long-term high-intensity operation. Through open data interfaces and intelligent scheduling algorithms, millisecond-level collaboration with WMS, sorting machines and other equipment is achieved to build a complete intelligent logistics ecosystem.

Advantages

The Circulating Vertical Conveyor brings revolutionary efficiency improvement to the distribution center. Its continuous circulation operation mode completely eliminates the idle waiting time of traditional equipment. The modular design supports rapid expansion and function adjustment, perfectly adapting to business volume fluctuations and scene changes. The intelligent early warning system combined with remote monitoring function greatly reduces operation and maintenance costs, making the overall efficiency of the equipment reach the industry-leading level, and becoming an indispensable core equipment for modern intelligent distribution centers.

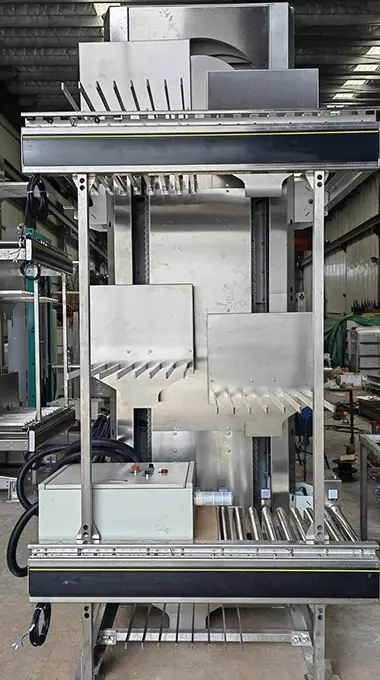

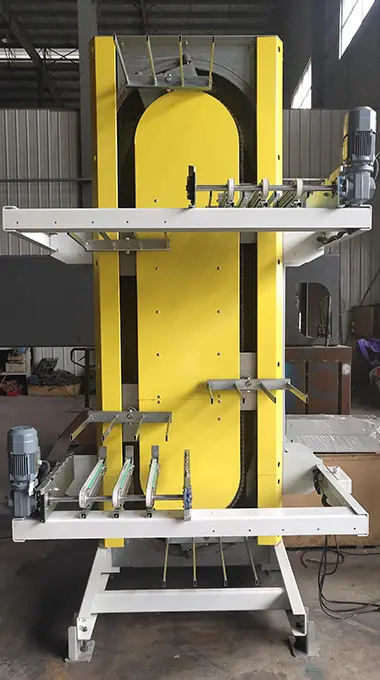

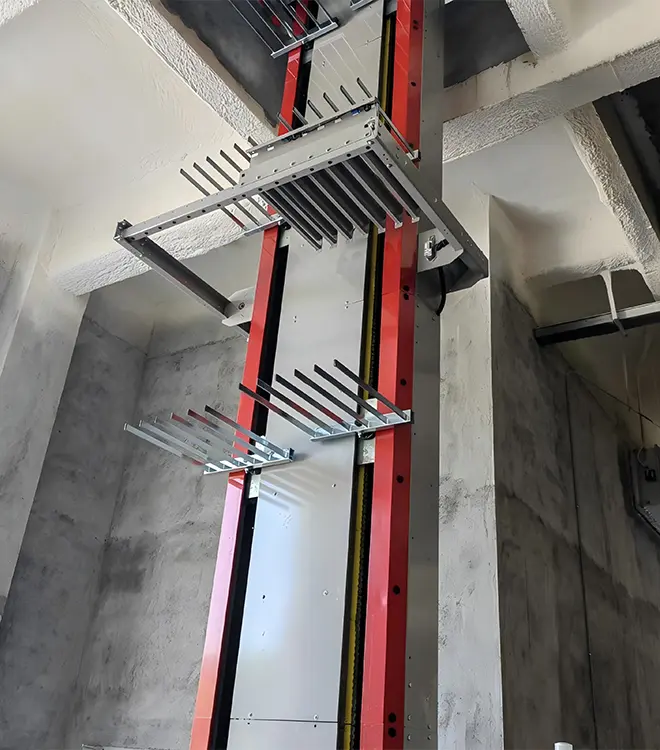

Gallery